In construction, environmental engineering, and agricultural projects, geomembrane plays a crucial role in ensuring effective waterproofing and containment. With its exceptional durability and flexibility, high-density polyethylene geomembrane is the most commonly used material for applications like landfills, ponds, reservoirs, and mining projects. However, not all geomembranes are created equal. Choosing a high-quality product is critical for the long-term success of your project, as cheap geomembrane alternatives may fail under pressure, leading to costly repairs or replacements.

In this blog, we will share practical tips on how to identify high-quality HDPE geomembrane to help you make an informed decision and achieve the best performance in your project.

1. Examine the Material Composition

The first step in identifying a quality high-density polyethylene geomembrane is to understand its material composition. High-quality HDPE geomembrane is made from virgin polyethylene resin, ensuring excellent strength, durability, and chemical resistance.

How to check?

Verify that the material contains 100% virgin polyethylene. Recycled materials, often found in cheap geomembrane, can compromise the membrane’s quality and lifespan.

Request a technical data sheet from the manufacturer to confirm the material specifications.

Why does it matter?

Using virgin HDPE ensures the geomembrane can withstand environmental stress, chemical exposure, and UV radiation without degrading over time.

2. Evaluate Thickness and Uniformity

The thickness of a geomembrane is directly related to its durability and performance. A thicker membrane provides better puncture resistance and longevity, making it ideal for demanding applications.

Key points to consider:

Measure the geomembrane’s thickness using a micrometer. A high-quality product will have consistent thickness across the entire surface.

Avoid cheap geomembrane that may have thin or uneven sections, as these can lead to premature failure.

Pro Tip:

For critical projects like landfills or mining applications, opt for a high-density polyethylene geomembrane with a thickness of 1.5 mm to 2.5 mm for maximum durability.

3. Assess Tensile Strength and Puncture Resistance

A high-quality geomembrane must have excellent tensile strength and puncture resistance to handle stress, movement, and sharp objects.

What to check?

Review the geomembrane’s tensile strength specifications, which should comply with international standards like ASTM or ISO.

Perform a puncture resistance test to ensure the material can withstand pressure without tearing.

Why it matters:

Poor puncture resistance is a common issue in cheap geomembrane, leading to leaks and compromised containment, especially in rough or uneven terrains.

4. Test for Chemical and UV Resistance

High-density polyethylene geomembrane is renowned for its resistance to chemicals and UV radiation. This property is essential for projects exposed to harsh environmental conditions, such as industrial waste containment or open ponds.

How to verify:

Ask for chemical resistance test reports from the manufacturer. A reliable HDPE geomembrane should resist acids, alkalis, oils, and solvents.

For UV resistance, ensure the product has undergone long-term UV aging tests to guarantee performance under direct sunlight.

Warning:

Cheap geomembrane often skips these critical tests, making it unsuitable for outdoor or chemically aggressive environments.

5. Inspect Manufacturing Standards and Certifications

Reputable manufacturers of high-density polyethylene geomembrane adhere to strict industry standards and quality controls. Certifications are an excellent indicator of a reliable product.

What to look for:

Check if the geomembrane meets international standards like ASTM D5199, GRI-GM13, or ISO 9001 certification.

Verify that the manufacturer provides quality control certificates for their production process.

Why certifications matter:

They ensure the geomembrane’s performance, durability, and compliance with global safety standards, reducing the risk of project failures.

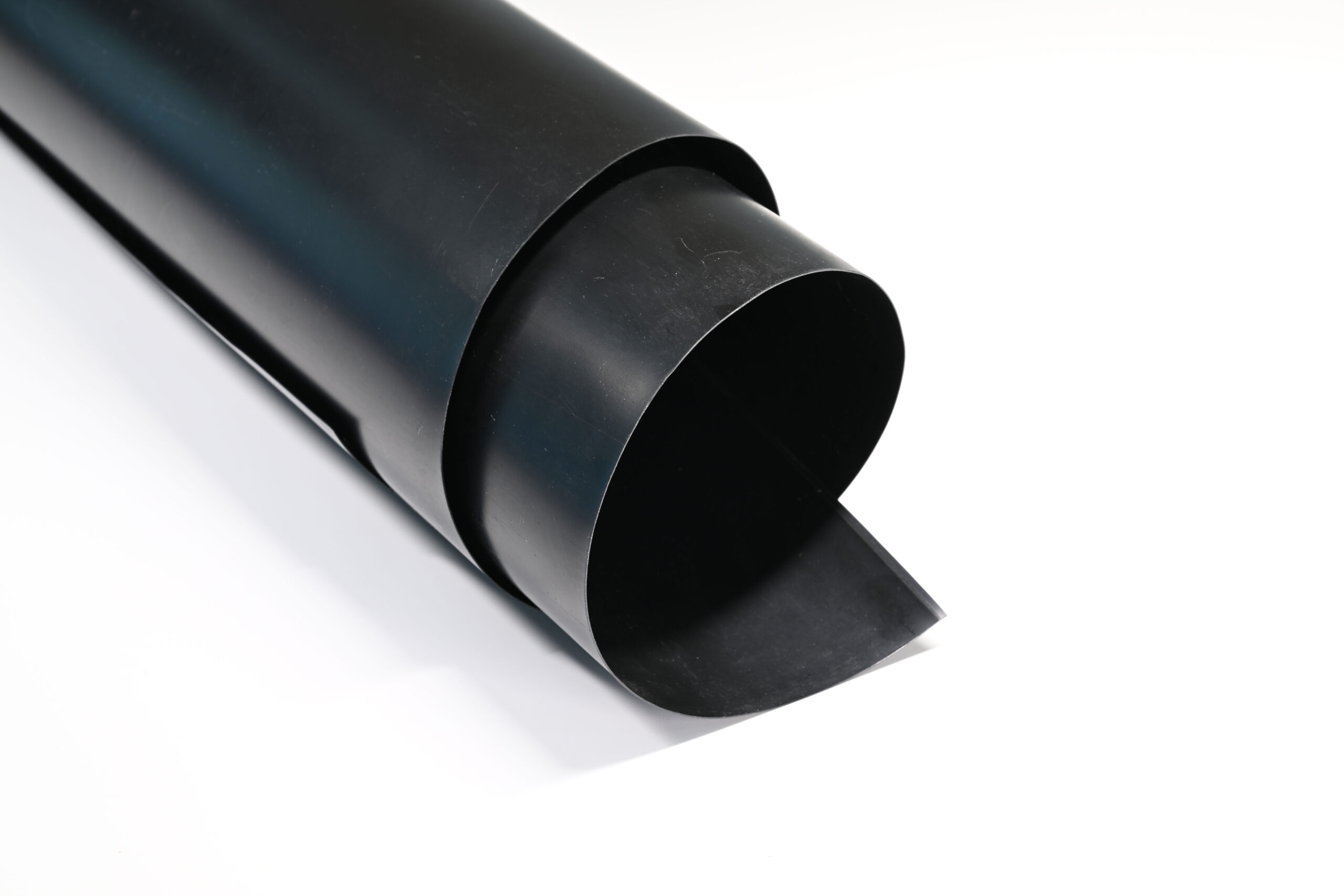

6. Perform Visual Inspection and Welding Tests

A visual inspection can reveal defects or inconsistencies in the geomembrane. High-quality materials should have a smooth, uniform surface without visible imperfections.

Steps for visual inspection:

Look for surface irregularities, such as bubbles, wrinkles, or discoloration.

Test the welding ability of the geomembrane. A quality high-density polyethylene geomembrane will weld cleanly and seamlessly using proper equipment.

Key Point:

Poor welding is a common problem in cheap geomembrane, as low-quality materials may not bond properly, resulting in leaks.

7. Compare Supplier Reputation and Reviews

Finally, selecting the right supplier is just as important as identifying the right product. A reputable supplier will offer consistent quality, reliable after-sales service, and professional technical support.

How to choose a supplier:

Research the supplier’s experience and reputation in the industry.

Read customer reviews and case studies to evaluate the performance of their products.

Request samples of the geomembrane to verify its quality before purchasing in bulk.

Pro Tip:

Avoid the temptation to buy cheap geomembrane from unknown suppliers, as the risks of poor performance and financial loss are high. Invest in a trusted supplier with proven expertise in high-density polyethylene geomembrane manufacturing.

Conclusion

Choosing a high-quality high-density polyethylene geomembrane is essential for the success of any containment or waterproofing project. By carefully examining the material composition, thickness, tensile strength, and resistance properties, you can ensure that the geomembrane meets your project’s requirements. Avoid falling into the trap of using cheap geomembrane, as it may lead to costly failures and environmental risks.

Always work with a reputable supplier who adheres to strict manufacturing standards and provides certified products. With these tips, you can confidently identify a premium geomembrane that delivers durability, reliability, and long-term performance.

Make the right choice today and protect your project with the strength and quality of high-density polyethylene geomembrane!