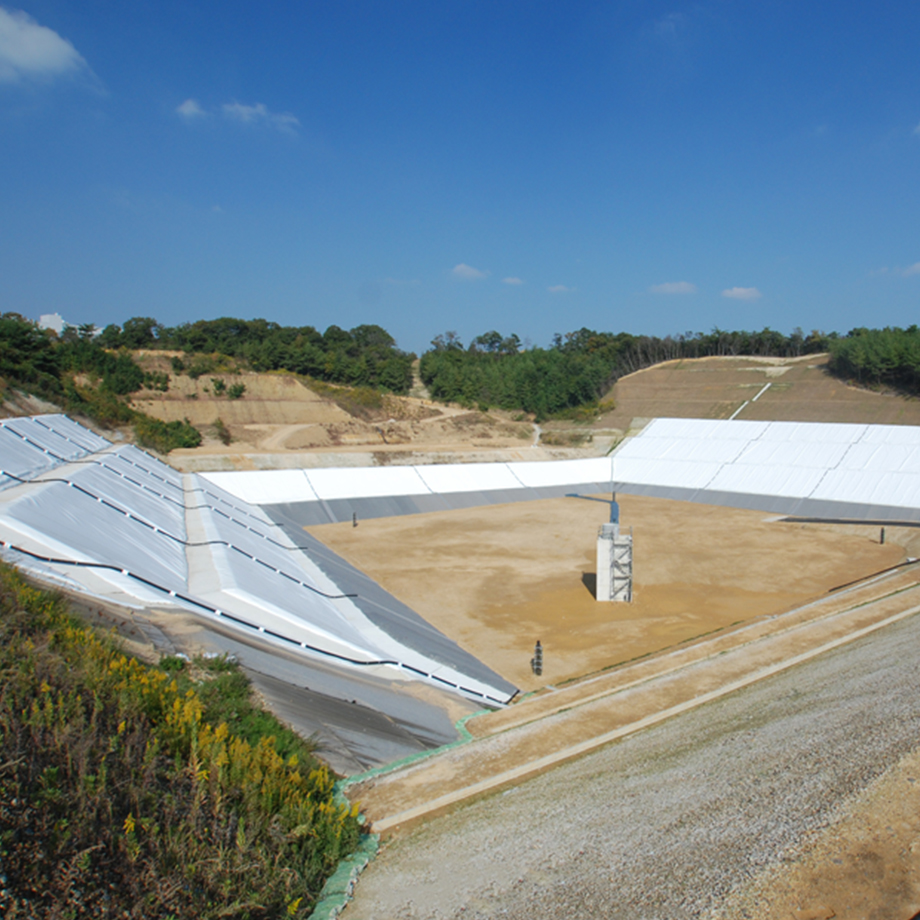

Geomembranes are synthetic membranes widely used in environmental, geotechnical, and hydraulic engineering to control fluid migration and provide containment solutions. These impermeable sheets are essential in applications such as landfill liners, water reservoirs, and mining operations. However, extreme weather conditions, such as intense heat, heavy rainfall, or freezing temperatures, can pose significant challenges to the performance and longevity of geomembranes.

1. Introduction to Geomembranes

Geomembranes are thin, flexible sheets made from materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM). They are designed to provide a barrier against liquids, gases, and contaminants, making them indispensable in environmental protection and infrastructure projects. However, their performance can be significantly affected by extreme weather conditions, which may lead to material degradation, leaks, or failures if not properly managed.

To address these challenges, engineers and project managers must implement specific protection measures and select the right type of geomembrane for the intended application. For instance, a damp-proof geomembrane is specifically designed to resist moisture penetration, making it ideal for areas with high humidity or frequent rainfall. Additionally, partnering with a reputable geomembrane manufacturer ensures access to high-quality materials and expert guidance on installation and maintenance.

2. Geomembranes in Extreme Weather Conditions

2.1. High-Temperature Environments

In regions with intense heat, geomembranes are exposed to prolonged UV radiation and thermal expansion. These factors can cause the material to become brittle, crack, or lose its impermeability over time. To mitigate these risks, geomembranes with UV stabilizers and heat-resistant properties are recommended. Proper installation techniques, such as allowing for thermal expansion and contraction, are also critical to maintaining the integrity of the geomembrane.

2.2. Heavy Rainfall and Flooding

Areas prone to heavy rainfall or flooding require geomembranes that can withstand prolonged exposure to water and resist hydrostatic pressure. A damp-proof geomembrane is particularly effective in such conditions, as it is designed to prevent water infiltration and maintain its structural integrity. Additionally, proper drainage systems and anchoring methods should be implemented to prevent the geomembrane from shifting or floating during floods.

2.3. Freezing Temperatures

In cold climates, geomembranes are at risk of cracking or becoming brittle due to freezing temperatures. Materials like HDPE and EPDM are more resistant to low temperatures and are often preferred for such environments. Insulation layers and protective covers can also be used to shield the geomembrane from extreme cold and ice formation.

2.4. Wind and Storms

Strong winds and storms can cause physical damage to exposed geomembranes, such as tearing or displacement. To protect against these risks, geomembranes should be securely anchored and covered with protective layers, such as soil or gravel. Regular inspections and maintenance are also essential to identify and repair any damage caused by wind or debris.

3. Protection Measures for Geomembranes

3.1. Proper Installation Techniques

The installation process plays a crucial role in the performance of geomembranes under extreme weather conditions. Key steps include:

Surface Preparation: Ensuring the substrate is smooth, free of sharp objects, and properly compacted to prevent punctures or tears.

Seaming and Welding: Using advanced techniques to create strong, leak-proof seams that can withstand thermal expansion and contraction.

Anchoring: Securing the geomembrane edges with trenches, anchors, or ballast to prevent displacement during storms or flooding.

3.2. Protective Layers and Covers

Adding protective layers, such as geotextiles, soil, or gravel, can shield geomembranes from physical damage, UV radiation, and temperature fluctuations. These layers also help distribute loads and reduce stress on the geomembrane.

3.3. Regular Inspections and Maintenance

Routine inspections are essential to identify and address potential issues, such as punctures, tears, or seam failures. Maintenance measures, such as cleaning debris and repairing damaged areas, can extend the lifespan of the geomembrane and ensure its continued effectiveness.

3.4. Choosing the Right Material

Selecting the appropriate geomembrane material for the specific environmental conditions is critical. For example, a damp-proof geomembrane is ideal for wet climates, while UV-stabilized geomembranes are better suited for sunny regions. Consulting with a reputable geomembrane manufacturer can help ensure the right material is chosen for the project.

4. The Role of a Reliable Geomembrane Manufacturer

Partnering with a trusted geomembrane manufacturer is essential for ensuring the quality, durability, and performance of geomembranes under extreme weather conditions. A reputable manufacturer will:

Provide high-quality materials that meet industry standards and project requirements.

Offer expert guidance on material selection, installation techniques, and protection measures.

Conduct rigorous testing to ensure the geomembrane can withstand specific environmental challenges.

Provide warranties and after-sales support to address any issues that may arise.

By working with a reliable geomembrane manufacturer, project managers can minimize risks, reduce costs, and ensure the long-term success of their projects.

Conclusion

Geomembranes are a vital component in many engineering and environmental projects, but their performance can be significantly impacted by extreme weather conditions. By understanding the challenges posed by high temperatures, heavy rainfall, freezing temperatures, and strong winds, project managers can implement effective protection measures and select the right materials for their needs. A damp-proof geomembrane is particularly valuable in wet climates, while UV-stabilized and cold-resistant geomembranes are ideal for sunny and cold regions, respectively.

Partnering with a reputable geomembrane manufacturer is crucial for ensuring the quality and durability of geomembranes. By following proper installation techniques, adding protective layers, and conducting regular inspections, the lifespan and effectiveness of geomembranes can be maximized, even under the most challenging weather conditions. With the right approach, geomembranes can continue to provide reliable containment solutions and contribute to the success of critical infrastructure projects worldwide.