In today’s construction and environmental protection industries, damp-proof geomembrane plays a crucial role in preventing water ingress and ensuring long-term durability of structures. This advanced material has become an essential component in various applications such as landfills, reservoirs, and civil engineering projects. But what exactly is a damp-proof geomembrane, and how is it made?

What is a Damp-Proof Geomembrane?

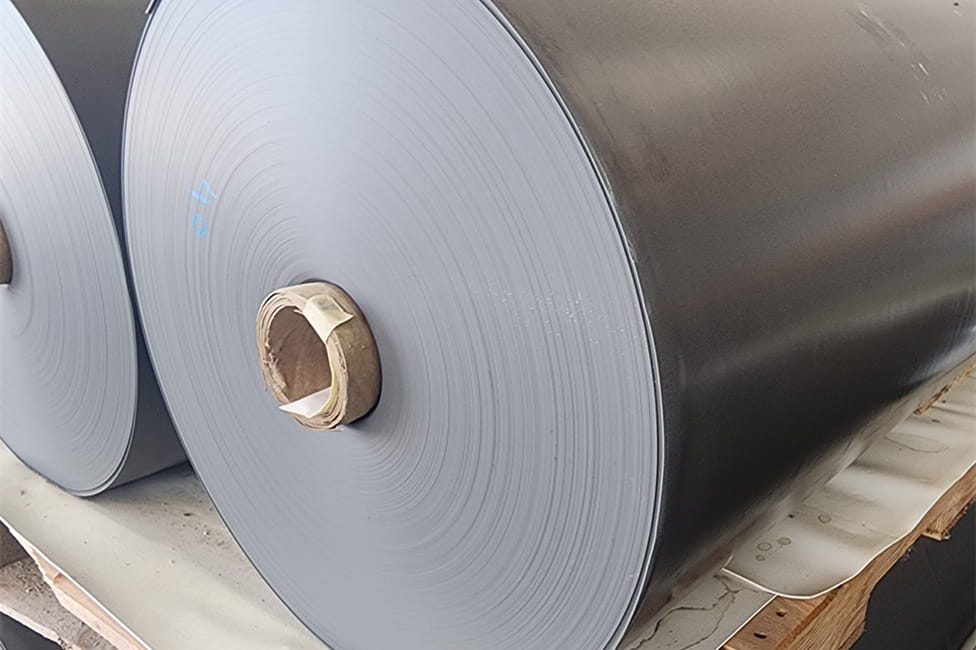

A damp-proof geomembrane is a synthetic membrane designed to prevent moisture from passing through the surface it covers. Unlike traditional waterproofing materials, geomembranes are made from highly durable polymers and are specifically engineered to provide long-lasting protection in harsh environments. This product is extensively used in containment applications such as lining ponds, landfills, tunnels, and water reservoirs, where preventing water seepage is critical.

The versatility of damp-proof geomembrane lies in its ability to perform effectively in a wide range of conditions, including extreme temperatures and high pressure. Its durability makes it a popular choice for environmental protection and construction, playing a critical role in reducing maintenance costs and prolonging the life of a project. But what goes into making this impressive material? The answer lies in the production process and the careful selection of raw materials.

The Production Process of Damp-Proof Geomembrane

The production of damp-proof geomembrane is a highly controlled and technical process that ensures the final product meets the stringent demands of its applications. Let’s break down the key stages of production.

1. Polymer Selection and Preparation

At the heart of a high-quality geomembrane is the polymer used in its manufacture. The most commonly used materials are high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM). These polymers are chosen for their ability to resist environmental stress, chemical degradation, and mechanical wear.

The first step in production is selecting the right polymer. The chosen material is then compounded with additives like stabilizers, antioxidants, and UV blockers, which enhance its durability and performance. For damp-proof geomembrane, this step is crucial, as the addition of these components helps the membrane maintain its properties over time, even when exposed to harsh weather and chemical substances.

2. Extrusion Process

Once the polymer mixture is ready, the next step is extrusion. In this phase, the polymer blend is heated to its melting point and then forced through a die to form a thin, continuous sheet. The thickness of the membrane is closely controlled, as it directly affects its performance. Thicker membranes offer better puncture resistance, while thinner membranes provide more flexibility.

During the extrusion process, the molten polymer is stretched in both the machine and transverse directions, which improves the tensile strength and elongation properties of the damp-proof geomembrane. This biaxial stretching ensures the membrane will maintain its integrity even under significant stress or movement in the ground.

3. Cooling and Calendering

After extrusion, the still-molten membrane is cooled and passed through a series of rollers in a process known as calendering. This step ensures that the damp-proof geomembrane has a uniform thickness and a smooth surface, which is essential for effective installation and bonding in construction projects.

The cooling phase is particularly important for preserving the mechanical properties of the material. If cooled too quickly or unevenly, the membrane could develop weak spots or warping. Therefore, careful temperature control during this stage is critical for ensuring the longevity and performance of the geomembrane.

4. Quality Control and Testing

Quality control is a vital part of the damp-proof geomembrane production process. During and after manufacturing, the membranes undergo rigorous testing to ensure they meet industry standards for strength, flexibility, chemical resistance, and permeability. These tests may include puncture resistance, tear strength, and stress crack resistance.

In addition to mechanical testing, samples are often subjected to accelerated aging tests to simulate long-term exposure to UV light, heat, and chemicals. This ensures that the damp-proof geomembrane will perform as expected in real-world conditions over many years.

Material Selection: Why It Matters

The performance of a damp-proof geomembrane is highly dependent on the materials chosen during production. Each type of polymer offers distinct advantages, making it important to select the right material for the specific application.

1.High-Density Polyethylene (HDPE)

HDPE is one of the most commonly used materials for geomembranes due to its excellent chemical resistance, UV stability, and low permeability. It is ideal for use in landfill liners and wastewater treatment facilities, where exposure to harsh chemicals and high levels of moisture is common. HDPE is also relatively cost-effective, making it a popular choice in the geomembranes market.

2.Low-Density Polyethylene (LDPE)

LDPE offers greater flexibility than HDPE, which makes it suitable for applications where movement or settlement of the substrate is expected. It is often used in pond liners, canal linings, and agricultural applications where flexibility and conformability to the surface are crucial.

3.Polyvinyl Chloride (PVC)

PVC geomembranes are known for their ease of installation and excellent flexibility. They are widely used in temporary covers, landfill caps, and water reservoirs. PVC membranes are particularly effective in cold climates, as they remain flexible at low temperatures.

4.Ethylene Propylene Diene Monomer (EPDM)

EPDM is highly durable and resistant to UV radiation and temperature extremes. This material is often used in roofing applications, water retention systems, and decorative ponds. EPDM is valued for its long service life and resistance to environmental stress cracking.

The Growing Demand in the Geomembranes Market

The geomembranes market has seen significant growth in recent years, driven by increasing awareness of environmental protection and the need for effective containment solutions. As industries like mining, agriculture, and waste management expand, the demand for damp-proof geomembrane materials continues to rise.

Innovations in material science and manufacturing processes have also contributed to the market’s expansion. New developments in polymer technology have made geomembranes more durable, easier to install, and more resistant to environmental degradation. This has opened up new applications for geomembranes, further fueling market growth.

Conclusion

The production of damp-proof geomembrane involves a sophisticated process of polymer selection, extrusion, cooling, and quality control. Each step is meticulously designed to ensure that the final product is capable of withstanding the demanding conditions in which it will be used. The selection of materials, whether it’s HDPE for chemical resistance or EPDM for flexibility, plays a critical role in determining the performance and longevity of the geomembrane.

As the geomembranes market continues to grow, understanding the intricacies of the production process and material selection will be essential for both manufacturers and users. By choosing the right materials and adhering to strict production standards, manufacturers can ensure that their geomembranes meet the needs of modern construction and environmental protection projects, offering reliable performance for years to come.